One of the main applications of lime

CaCO3 is in the industry of construction, or as a building material or synthetic limestone for roadbuilding or as an ingredient of cement or as starting material for the preparation of building lime by burning in the oven . However, because the weather is mainly caused by acid rain, stone powder stone powder CaCO3 (in the form of limestone) no longer used for the purpose of building on its own, and only as a material / main character construction materials.

Stone powder stone powder is also used in the purification of iron from iron ore in blast furnaces. Carbonate is heated in place to provide calcium oxide, forming a slag with various impurities present, and separated from pure iron.

In the petroleum industry, powdered lime stone CaCO3 is added to drilling fluids as a formation-bridging and filtercake sealing agent; it is also an important material to increase the density of drilling mud to control downhole pressure. Bot skins are added to the pool, as a corrector for maintaining pH and alkalinity to offset the acidic properties of the disinfectant agent.

It is also used as a raw material in the refining of sugar from sugar beet; It was heated in a furnace with coal to produce calcium oxide and carbon dioxide. Burned lime is then slaked in fresh water to produce a calcium hydroxide suspension for precipitation of impurities in raw water in carbonatation.

CaCO3 lime stone powder has traditionally been a major component of black chalk. However, modern production pollen mainly gypsum, hydrous calcium sulfate CaSO4 • 2H2O. Bot skin is a major source for development Seacrete, or Biorock. Stone powder precipitated CaCO3 (PCC), was dispersed in the form of mud, is a popular material for extra rubber gloves with the aim of achieving maximum savings in raw material costs and production.

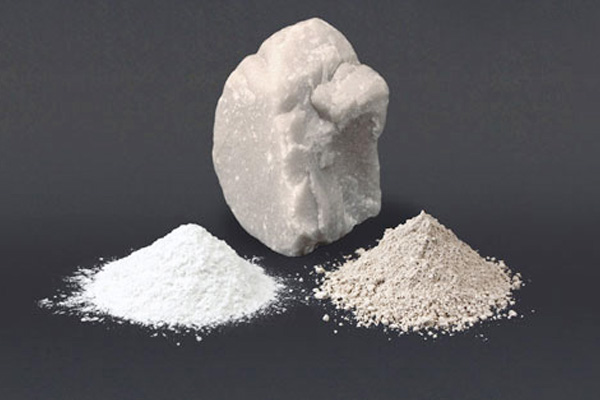

Lime stone powder CaCO3 ground (GCC) is an essential component in films microporous used in diaper babies and some films, such as building the pores are there people around the beads lime CaCO3 while the production of the film by biaxial stretching. GCC or PCC is used as a filler in the paper because they are cheaper than wood fiber. Market volume, leather boots are the most important types of fillers currently in use. Printing and writing paper can contain 10-20% CaCO3 stone powder. In North America, stone powder CaCO3 began to replace kaolin in paper production shade. Europe has been practicing as alkaline or acid paper paper charges for some decades. PCC has very good particle size and control, on the order of 2 micrometers in diameter, useful in coatings for paper.

Stone powder stone powder is widely used as an extender in paints, in particular matte emulsion paint where typically 30% by weight of the paint or chalk or marble. It is also a common side in plastics. Some examples include about 15 to 20% loading of chalk in unplasticized polyvinyl chloride (uPVC) drain pipe, 5-15% loading of stearate coated chalk or marble in uPVC window profiles. PVC cable can use stone powder CaCO3 at loads up to 70 PHR (percentage of plastic parts) to improve the mechanical properties (tensile strength and elongation) and electrical properties (volume resistor). Polypropylene compounds are often filled with leather bot to increase stiffness, a requirement which becomes important at high temperature use. Here rate is usually 20-40%. It is also commonly used as a filler in thermoset resins (where materials and casting bulk) and has also been mixed with ABS, and other components, to form some sort of compression molded "land clay "poker chips. Precipitated CaCO3 powder stone, done by dropping calcium oxide in water, used by itself or with additives such as a layer of white paint, called lime.

CaCO3 lime stone powder is added to a wide range of commercial and himself as adhesives, sealants, and decorating fillers. ceramic tile adhesives typically contain 70-80% limestone. Decorative crack fillers contain similar levels of marble or dolomite. It is also mixed with putty in setting stained glass windows, and as an antioxidant to prevent glass from sticking to kiln shelves when firing glaze and paint at high temperature.

In the application of ceramic / glass, stone powder CaCO3 known as Whiting, and is a common component of many enzymes in its white powder. When this enzyme containing fired in the kiln, the whiting acts as a flux material in yeast. Ground stone powder CaCO3 is an abrasive (both as scouring powder and is a component of creams household cleaners), especially in the form of calcite of it, in which the hardness is relatively low 3 on ladder Mohs hardness of minerals, and therefore will not scratch glass and most other ceramics, enamel, copper, iron, steel, and have a moderate effect on soft metals such as aluminum and copper. A paste made from flour and water ice CaCO3 deionized can be used to clean silver staining.