Components, Applications of Talc Powder

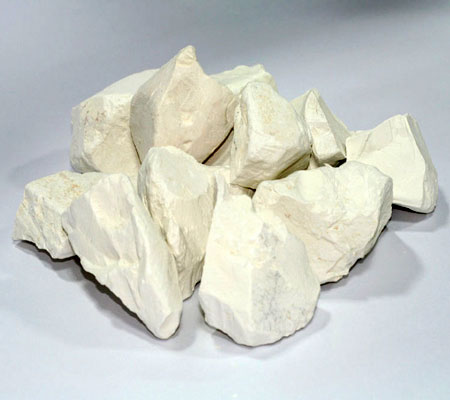

Talc derived from Persian language, Arabic is talq, is a hydrated magnesium silicate mineral with chemical formula is H2Mg3 (SiO3) 4 or Mg3Si4O10 (OH) 2. Talc is used extensively in the form of unconsolidated called talc. Talc crystallize in us a little inclined gap.Talc the softest minerals. Talc is insoluble in water, but little talc in diluted mineral acid solution. Its color ranges from white to gray or green and it has a greasy feel.

Place of origin

Talc is a mineral formed from the metamorphism of the mineral magnesium as pyroxene, amphibole, olivine presence of carbon dioxide and water. This process creates the corresponding stone called carbonate talc.

Talc was originally formed by hydration and carbonation of serpentine, via the following reaction:

Carbon Dioxide serpentine + talc + magnesite + water →

Talc is also generated through contact metamorphic process by reaction between dolomite and silica, dolomite chemical called skarn;

Silica + dolomite + calcite + Water → Talc + Carbon Dioxide

Talc is also made up of magnesium chlorite and quartz schists continent and eclogite metamorphic reactions:

Chlorite + quartz + H2O → kyanite + Talc

In this reaction, the ratio of talc and kyanite dependent on aluminum content in the aluminum-rich rocks. This process discharged under conditions of high pressure and low temperatures often create phengit, garnet, glaucophane in general continental plates. The stone is white, friable and fibrous called white slate.

Grade Minerals Talc under 24 face (tri-octahedral); Its structure is similar to the structure of pyrophyllit, but the magnesium in the octahedral sites.

Dregs

Talc is a common metamorphic mineral in metamorphic ultramafic rocks such as soapstone (talc high rock), and in white and slate slate continent. The white slate form can be found in metamorphic Francisc western United States, western Europe under permissive Alps especially in Italy, certain areas of the Musgrave Block, and as accommodating Himalaya orogenic belt.

Talc carbonated ultramafic rocks metamorphosed from the very specific to the crater of Archaean age, like belts of komatiite Yilgarn Craton in Western Australia. Ultramafic talc carbonate is found in Lachlan fold belt, eastern Australia, Brazil, Guiana Shield, and the ophiolite belts of Turkey, Oman and the Middle East.

Commercial talc may include the Mount Seabrook talc mine, Western Australia, formed from the metamorphism of ultramafic intrusive rocks.

To use

High talc blue gray soapstone or steatite called used in stoves, sinks, electrical switchboards ... Talc is also used in cosmetics (talc), lubricants, and in paper Filter. Talc is used in baby diapers. Use as tailors chalk, weld or cut metals.

Talc is also used in food or pharmaceutical. In medicine talc pleurodesis agent whose role is to prevent recurrent pneumothorax. According to the European Union this matter has number E553b.

Talc is widely used in ceramic industry. In the ceramic art, melt is added to increase the brightness and increased heat resistance when baked avoid breakage. In stoneware, a small amount of talc is added to increase the reliability and vitrification. MgO material is produced by electrolysis of molten.

Talc applications in the automotive industry

Each year about 200 thousand tons of technical talc is mixed with polypropylene (PP). This talc powder substances active but reinforced, creating stiffness, anti-deformation at high temperatures and increased stability of product size PP.

The current trend in the automotive industry is the fabrication of thin parts, light and precise dimensions, this requires that plastic has a higher rheology. On the other hand, the high-melting plastic back or becoming brittle.

Recently, Rio Tinto Minerals Company has developed a talc (HAR) superfine, allowing better positioning particles by pressure casting process, due to better dispersion of the resin to maintain stiffness for molded parts.

Talc HAR bend coefficient increases to 20% increase of deformation temperature of PP compounds with low thermal expansion coefficient than 20% and low shrinkage rate, while not reducing the viscosity of molded parts. PP containing talc HAR type used outside of automotive parts (dampers, balance parts and fenders) and parts needed high impact resistance.

In rubber, talcum powder is used as an additive for the processing and reinforcing fillers.

Talc also help tire manufacturers reduce the thickness and weight of the tire. This not only increases rolling resistance, it also makes tires are much cheaper to produce. Additional rubber HAR talc may also lead to cost savings while air permeability unchanged compared with the rubber material used.

The cars now contain up to 1,000 rubber components and plastic and a vehicle containing an average of 8 kg of talcum.

Use waterproof talc in tires helping manufacturers make tires lighter and thinner tires with low rolling resistance, and less fuel consumption. Talc also save energy by reducing the viscosity of rubber compounds to make molded parts and molding easier.

Currently the company is providing telecom Chemical Talc types imported from China, India ...